The following points highlight the five main types of split-phase motors. The types are: 1. Resistance-Start Single-Phase Induction Motor 2. Capacitor-Start Single-Phase Induction Motor 3. Capacitor-Start Capacitor-Run Single-Phase Induction Motor 4. Permanent Capacitor Single Phase Induction Motor 5. Shaded-Pole Motor.

Type # 1. Resistance-Start Single-Phase Induction Motor:

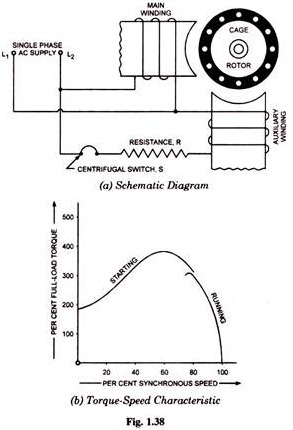

It is a form of split-phase motor having a high resistance connected in series with the auxiliary or starting winding, as illustrated in Fig. 1.38 (a).

A typical torque-speed characteristic is shown is Fig. 1.38 (b). The starting torque is 1.5 times to twice the full-load starting torque and starting current is 6 to 8 times full-load current. The speed regulation of a resistance-start single phase induction motor is very good. The per cent slip in most fractional kilowatt split-phase motors is about 4-6 per cent. Such a motor may operate with a power factor of 0.55-0.65 and efficiency of 60-65 per cent.

Owing to their low cost, resistance start split-phase motors are most popular single phase motors. These motors are made in fractional kilowatt (1/20 to 1/4 kW) ratings with speed ranging from 2,875 to 700 rpm. Such motors find wide applications for low inertia loads, continuous operating loads and applications requiring moderate starting torque such as for driving washing machines, fans, blowers, centrifugal pumps, domestic refrigerators, duplicating machines, office appliances, food processing machines, woodworking tools, grinders, oil burners etc. Because of low starting torque these motors are seldom employed in sizes larger than 1/4 kW.

The direction of rotation of a capacitor-start induction motor may be reversed by inter-changing the connections to the supply of either the main or starting winding. The noteworthy point is that reversal of a split-phase induction motor takes place only when it is at rest and the starting switch is in its normally closed de-energized position.

Type # 2. Capacitor-Start Single-Phase Induction Motor:

Fundamentally this motor is very similar to the resistance- start split-phase motor except that the starting winding has a few more turns and consists of a heavier wire than the starting winding of a resistance-start motor; there is also a large electrolytic capacitor in place of resistor. The capacitor- start motor develops a greater starting torque than does an equally rated resistance-start motor. The line current of a resistance-start motor was found to be two-third higher than line current of a corresponding capacitor-start motor, while the starting torque of the capacitor-start motor was twice of that of resistance-start motor.

It is to be noteworthy that the capacitor-start motor differs from the resistance-start motor only during the starting period, for it develops more starting torque (about 3.5-4.5 times full-load torque) with a lower inrush current. After the machine attains normal speed and the starting winding is cut out, its operating characteristics are identical to those of a corresponding resistance-start motor.

Capacitor-start motors are manufactured in rating ranging from 1/10 kW to 3/4 kW, but larger sizes are also available. They are widely used for heavy duty general purpose applications like refrigerator units, air-conditioners, compressors, jet pumps, sump pumps, centrifugal pumps, compressors, conveyors, fans, blowers, farm and home workshop tools, oil burners etc.

Type # 3. Capacitor-Start Capacitor-Run Single-Phase Induction Motor:

ADVERTISEMENTS:

The capacitor start capacitor-run motor is similar to capacitor-start, induction-run motor, except that the auxiliary winding and a capacitor remain connected in the circuit at all times. Of course, such as motor consists of two different capacitors-one small value oil impregnated paper continuous rating capacitor CR and another much larger value electrolytic short-duty capacitor Cs, as illustrated in schematic diagram given in Fig. 1.39 (a).

Such a motor operates as a two-phase motor from single phase supply, thereby, producing a constant torque and not a pulsating torque, as in other single-phase motors. Besides their ability to start heavy loads they are extremely quiet in operation, have better efficiency (55-65%) and power factor (0.8-0.95) when loaded and develop up to 25% greater overload capacities. They are indeed splendid machines where the load requirements are severe as in case of compressors, refrigerators and fire stokers, pumps, conveyors etc. The disadvantage of such machines is only high cost. These motors are often employed requiring a quiet operating motor such as in hospitals, studios etc.

In recent years, home air-conditioners have become extremely popular. In many cases, the electrical system in the home may not have the capacity to handle the electrical load of the air-conditioner(s). For this reason, capacitor-start capacitor-run motor has found more wide spread use in the compressors. Both the starting and running currents are low— full-load current may be 3/4th of that for an equivalent capacitor-start motor.

Such motors have become increasingly popular and are now manufactured in the larger sized single-phase motors” where previously only repulsion-start motors were available. A typical torque-speed characteristic is shown in Fig. 1.39 (b). The direction of rotation of motor may be reversed by interchanging the connections to the supply of either the main or auxiliary winding.

Type # 4. Permanent Capacitor Single Phase Induction Motor:

ADVERTISEMENTS:

Permanent capacitor single-phase induction motor, also sometimes called the single-value capacitor-run motor, has two stator windings placed mutually 90 electrical degrees apart. The main or running winding is connected directly across the single phase ac supply. A capacitor in series with the auxiliary winding is also connected across the supply lines.

The auxiliary winding is always in the motor circuit, and therefore, the operation of the motor when loaded resembles more closely to that of a 2-phase motor. One advantage of such operation is that the rotating field developed by the two stator windings is a more nearly uniform, and therefore, the motor is quieter in operation.

The other advantages of such a motor are:

ADVERTISEMENTS:

(i) Increased pull-out torque

(ii) A higher power factor (0.8-0.95),

(iii) Higher operation efficiency (55- 65 per cent) and

(iv) Smaller full-load line current.

ADVERTISEMENTS:

The permanent capacitor induction motor is more expensive than the equivalent resistance-start or capacitor—start induction motor mainly owing to the increased cost of auxiliary winding which is now wound with thicker wire and consists of as many turns as the main winding.

A unique feature of such a motor is that it can be very easily reversed by an external switch, provided the two windings are identical. Because of absence of starting switch it is possible to reverse the leads of either winding while the motor is running.

Such motors are widely used in table and ceiling fans, blowers, oil burners, room coolers, portable tools, other domestic and commercial electrical appliances, where low starting torque is required.

Because of the simplicity of reversal of motor, such motors are often used to operate devices that must be moved back and forth frequently such as induction regulators, rheostats, furnace controls, valves and arc-welding controls.

Because of the absence of starting switch, it is possible to run a permanent (or single value) capacitor-run motor over a wide range of speeds, and such a motor has many applications where adjustable speed is required. Such a motor can be arranged for an adjustable speed by the use of a tapped winding or an auto-transformer regulator. It is known that the torque developed in an induction motor is proportional to the square of the applied voltage. For a given load, therefore, if the applied voltage is reduced, the motor will operate with increased slip to develop the required torque. Thus the speed can be controlled by varying the voltage applied to the motor.

Type # 5. Shaded-Pole Motor:

As illustrated schematically in Fig. 1.41 (a) the shaded-pole motor usually has salient poles with one portion of each pole surrounded by a short-circuited turn of copper called a shading coil. Induced currents in the shading coil cause the flux in the shaded portion of the pole to lag the flux in the other portion. The result is like a rotating field moving in the direction from the unshaded portion to the shaded portion of the pole, and a low starting torque is developed. A typical torque-speed characteristic is shown in Fig. 1.41 (b).

Starting torque is very small (about 40-80% of full-load torque). The efficiency is quite low (20 to 50%). Power factor is also very poor ranging from 0.5 to 0.6. It has little overload capacity. Speed falls with the decrease in applied voltage. Speed can be varied by varying the voltage applied across its stator winding (by using an auto-transformer, tapped reactance coil or by using tapped exciting winding). Shaded- pole motors are least expensive type of small power motors.

Because of their poor starting torque, low power factor and poor efficiency, such motors are only suitable for low power applications such as for toys, small fans, electric clocks, hair dryers, time phonographs, slide projectors, humidifiers, small business machines (photocopying machines, vending machines, advertising displays etc.) and other similar applications. They are manufactured in small sizes ranging from below 5 W to about 100-150 W. They are available with built-in gear reducers to give almost any speed (as low as below 1 rpm.).