List of Pressure Measuring Devices. And the devices are: 1. The Barometer 2.Piezometer or Pressure Tube 3. Manometers 4. The Bourdon Gauge 5. The Diaphragm Pressure Gauge 6. Micro Manometer (U-Tube with Enlarged Ends) .

1. The Barometer:

The barometer is a device meant for measuring the local atmospheric pressure. Fig. 2.18 shows a mercury barometer which consists of a 1 metre long glass tube closed at one end and completely filled with mercury and kept inverted in a bowl of mercury. A small quantity of mercury will drop into the bowl and thus a vacuum forms at the upper end of the tube.

The atmospheric pressure acting on the surface of mercury in the bowl will support a mercury column in the tube. Let h be the height of mercury column in the tube measured above the surface of mercury in the bowl.

ADVERTISEMENTS:

Let Pa be the atmospheric pressure intensity

The height of the mercury column at sea level, is approximately 760 mm of mercury.

Atmospheric pressure head at sea level = 760 mm of mercury.

ADVERTISEMENTS:

The space above the mercury in the tube will contain vapours of mercury.

This space is called Torricellian vacuum.

Note:

Mercury is ideally suited for use in a barometer due to its high density (needing therefore only a short tube) and its very low vapour pressure.

ADVERTISEMENTS:

The altitude of a place and weather conditions influence the reading of the barometer. A reading of a barometer recorded at a spot indicates only the local atmospheric pressure.

The International standard atmospheric pressure is 101.325 kPa corresponding to 10.325 m of water or 760 mm of mercury.

This device consists of a partially evacuated corrugated box prevented from collapsing by a strong spring. Pressure variations cause the front part of the box to deform inwards or outwards so that the pull of the spring will just resist the force due to the pressure of the atmosphere.

ADVERTISEMENTS:

These small displacements are amplified and move a pointer provided over a calibrated scale.

This instrument is conveniently used as a household barometer. This device consists of a glass tube bent at the lower part to form a U-tube. The open end of the U-tube is enlarged. This enlarged part takes the place of the bowl or reservoir of the ordinary barometer. An iron block of small weight is supported on the mercury surface partly by up thrust of mercury on it and partly by a counterweight.

ADVERTISEMENTS:

The iron block and the counterweight are connected by a string taken over a pulley. Variation of atmospheric pressure brings about rise and fall of the mercury surface in the open end of the U-tube which in turn causes the pulley to rotate by some angle. A pointer attached to the pulley will move over a circular scale from which the atmospheric pressure may be read.

2. Piezometer or Pressure Tube:

The piezometer is used to measure the static pressure head of a liquid flowing at any section of a pipe. It consists of a tube whose open lower end is mounted flush with the inside wall of the pipe. The other end of the tube is exposed to the atmosphere. In the arrangement shown in Fig. 2.21 and 2.22 the height h to which the liquid rises in the tube represents the pressure head at the level A where the tube is connected to the pipe.

The piezometer may also be so shaped and connected to the pipe so that the pressure head at the level of the centre of the pipe may be directly obtained.

Limitations of a Piezometer:

The piezometer has limitations for its use due to the following reasons:

(i) It is very difficult or impracticable to measure high pressures. Particularly for liquids of low specific gravity, the height of the liquid column in the piezometer will be inconveniently high requiring a very long piezometer tube.

(ii) The piezometer cannot work for negative gauge pressure since air would flow into the container through the tube.

(iii) Capillary errors are likely to arise when the tubes are of diameters 10 mm or less.

(iv) Rapid changes of pressure which may take place continuously cannot be effectively measured. This is because change in the piezometer level will lag behind corresponding rapid change of pressure.

The piezometer tube may take the form shown in Fig. 2.23 for measurement of small negative gauge pressures. In this arrangement, the free surface of the liquid in the tube will be at a level lower than the level A inside the container where the pressure is to be gauged. If the free liquid surface in the tube is h units below A, then the pressure head at A

= ha = – Sh units of length of water,

where, S – Specific gravity of the liquid.

3. Manometers:

i. The U-Tube Manometer (The Double Column Manometer):

Manometers are pressure gauging devices using columns of different liquids. The fluid whose pressure is to be determined is called the metered fluid while the other fluid is called the manometer fluid. The manometer fluid may be of higher density or lower density than that of the metered fluid. These devices can be used to gauge pressures of liquids as well as gases. Manometers have connecting U-shaped tubes containing different fluids.

In a manometer when one limb of the device is open to the atmosphere it records the pressure of the source connected to the other limb. When both the limbs are connected to pressure sources, the manometer records the difference of pressure between the two pressure sources. Accordingly, these manometers are called simple manometer and differential manometer.

The pressure of a fluid in a pipe may be measured by using a glass U-tube containing a heavier liquid which does not mix with the fluid in the pipe.

Suppose the pipe contains water, and mercury is used as the measuring liquid. Let the level EF correspond to the surface of contact of the two liquids. Let X be the centre of the pipe.

ii. Inverted U-Tube Manometer:

Sometimes a lighter liquid is used in a manometer. In such a case an inverted manometer is used (Fig. 2.39).

Pipes A and B contain liquids of specific gravity Sa and Sb respectively. The inverted manometer contains a liquid of specific gravity S. In such an arrangement even for small differences of pressure between A and B large deflections of the manometer liquid will occur. Hence measurements can be made accurately. Let w = Specific weight of water.

∴ Specific weight of liquid in A and B are respectively Saw and Sbw.

Measurement of Negative or Suction Pressure:

Fig. 2.43 shows a pipe A containing water at a pressure Pa. The pipe is connected to a U-tube containing a heavy liquid of specific gravity S. (Usually mercury is used as the measuring liquid). Fig. 2.43 shows the levels of the surfaces of the measuring liquid. Let y be the reading of the manometer. Let the upper surface of the measuring liquid be h units below the centre of the pipe.

Single Column Manometer:

The single column manometer shown in Fig. 2.55 is a modified form of the ordinary U-tube manometer. This manometer also has two limbs, one of which is made very large in area compared with the other. The area of the larger limb (also called the basin) may be made 100 times the area of the other limb. The manometer contains a heavy liquid like mercury. The pipe in which the pressure is to be determined is connected to the larger limb.

Any pressure change in the pipe may only produce a very small change in level of the manometer liquid surface in the basin. This change in level may be neglected. Hence the reading in the narrow tube only is to be taken. Since there is no need to take any reading corresponding to the liquid surface in the basin, it need not be made transparent. Usually it is made of iron. The other limb i.e., the narrow tube may be vertical or inclined, to make it more sensitive.

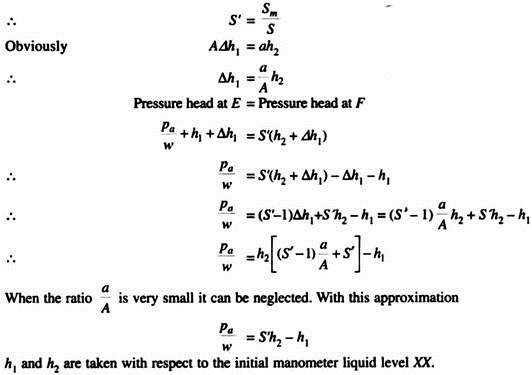

Let XX be the level of manometer liquid in the basin and the narrow tube when the manometer is not connected to the pipe. Let after connecting the pipe to the manometer the drop in manometer liquid level in the basin be ∆h1.

Let h2 = rise of manometer liquid level in the narrow limb.

h1 = Height of centre of pipe above XX.

A = Cross-sectional area of the basin.

a = Cross-sectional area of the narrow limb.

S = Specific gravity of the liquid in the pipe.

Sm = Specific gravity of the liquid in the manometer.

S’ = Specific gravity of the liquid in the manometer relative to the liquid in the pipe.

iv. The Inclined Tube Manometer:

This is an improvement over the single column manometer. In this case the manometer tube is made inclined in order to make it more sensitive. Fig. 2.56 shows this type of manometer. In this case the displacement of the heavy liquid in the narrow tube is relatively greater and hence readings can be taken more accurately.

4. The Bourdon Gauge:

This device consists of a metallic tube of elliptical section closed at one end A, the other end B being fitted to the gauge point where the pressure is to be measured. As the fluid enters the tube, the tube tends to straighten.

By using a pinion-sector arrangement the small elastic deformation of the tube is communicated to a pointer in an amplified manner. The pointer moves over a graduated dial. The device is calibrated by subjecting it to various known pressures.

The Bourdon gauge is suitable for measuring not only high pressures such as those in a steam boiler or a water main but also negative or vacuum pressures. A gauge which is so devised to measure positive as well as negative pressures is called a compound gauge.

5. The Diaphragm Pressure Gauge:

This device is based on the same principle as that of the Bourdon gauge. In this case a corrugated diaphragm is provided instead of the Bourdon tube. When the device is fitted to any gauge point, the diaphragm will undergo an elastic deformation.

This deformation is communicated to a pointer which moves on a graduated scale indicating the pressure. It may be noted that this device works on the same principle as that of the aneroid barometer. This device is found suitable for measuring relatively low pressures.

6. Micro Manometer (U-Tube with Enlarged Ends):

In order to increase the sensitivity of the U- tube gauge enlarged ends are provided as shown in Fig. 2.59. Such an arrangement is called a micro manometer. In this device we use two immiscible manometer liquids. Let s1 and s2 be the specific gravity of the two manometer liquids (let s1 > s2); the denser liquid will fill the bottom of the U-tube.

Let A = area of each enlarged end

a = area of the tube

When the pressures applied to the two limbs are equal, i.e. when p1 = p2 let the surface of separation between the two liquids be XX.

Let in this condition the head of the lighter manometer liquid be h above XX. Pressure at XX must be the same in the two limbs.

px = s2wh