List of Important Alloys and their Composition: (1) Aluminium Alloys (2) Copper Alloys (3) Magnesium Alloys (4) Nickel Alloys (5) Steel Alloys.

(1) Aluminium Alloys:

These are preferred to pure aluminium for constructional purposes. They are hard and strong. They contain copper, silicon, magnesium, manganese, iron and nickel in various combinations.

Following are the important alloys of aluminium:

(i) Aldural

ADVERTISEMENTS:

(ii) Aluminium bronze

(iii) Duralumin

(iv) Y-alloy.

(i) Aldural:

ADVERTISEMENTS:

This is also known as the Alclad and it is duralumin with a thin coating of pure aluminium. The thickness of layer of pure aluminium is about 5 per cent of thickness of core and such a layer prevents corrosion due to salt water.

(ii) Aluminium Bronze:

This is in fact copper alloy. It consists of 10 to 22 per cent of aluminium and 90 to 78 per cent of copper. It is very strong, hard, light, elastic and malleable yellowish-brown alloy. It is a corrosion resisting alloy and has many applications for die-casting, pump rods, etc. It is a substitute for brass.

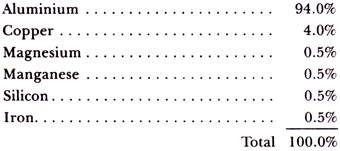

(iii) Duralumin:

ADVERTISEMENTS:

This is a very important alloy of aluminium.

Its composition is as follows:

Its specific gravity is about 2.85. It possesses the property of age hardening i.e. it acquires hardness after about 2 to 3 days when quenched in water from 500°C. It is quite strong and it has high electrical conductance. It is used in aircraft and automobile industries, for making electric cables, in surgical and orthopaedic implements or gadgets, etc.

ADVERTISEMENTS:

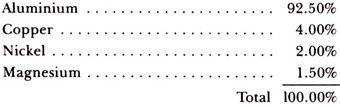

(iv) Y-Alloy:

Following is the composition of this alloy:

This alloy is a good conductor of heat and it possesses high strength at high temperatures. It is used for making pistons of engines, cylinder heads, gear boxes, propeller blades, etc.

(2) Copper Alloys:

ADVERTISEMENTS:

These alloys are broadly divided into two categories:

1. Brasses

2. Bronzes.

a. Brasses:

The brass is an alloy of copper and zinc and minor percentages of other elements, except tin, may be added. This is the most widely used copper alloy. It is stronger than copper and is used in structural applications. It also possesses good corrosion resistance. It can be cast into moulds, drawn into wires, rolled into sheets and turned into tubes. Very often 1 to 3% of lead is added to brass for improving its machining properties.

Following are the common varieties of brass:

(i) Cartridge Brass:

It consists of 70% copper and 30% zinc. It is ductile and it possesses high tensile strength. It is used for cartridges, tubes, springs, etc.

(ii) Delta Metal:

It contains 60% copper, 37% zinc and 3% iron. Its resistance to corrosion is high. It may even be used in place of mild steel to resist corrosion.

(iii) Low Brass:

It contains 80% copper and 20% zinc. It is moderately strong and it is used for pump lines, ornamental metal work and musical instruments.

(iv) Muntz Metal or Yellow Metal:

It contains 60% copper and 40% zinc. It has high strength. It is used for casting, condenser tubes, etc. and is a very popular alloy for hot working processes.

(v) Naval Brass:

This is an exception to the general rule for brass. It contains about 1 per cent of tin. When one per cent tin is added to the muntz metal, it is called the naval brass and when it is added to the cartridge metal, it is called the admiralty metal. It is used for marine and engineering castings such as condenser tubes pump parts, motor boat shafting, etc.

(vi) Red Brass or Red Metal:

It contains 85% copper and 15% zinc. It resists firmly the action of corrosion and is superior to copper for handling water. It is used for plumbing lines, electrical sockets, etc.

(vii) White Brass:

It contains 10% copper and 90% zinc. It is more or less similar to zinc except that addition of copper makes it hard and strong. It is used for ornamental work.

(viii) Yellow Brass:

It contains 65% copper and 35% zinc. Its specific gravity is 8.47. It is very strong and it is also known as the common high brass or standard brass. It is used for plumbing accessories, lamp fixtures, grillwork, screws, rivets, tubes, etc.

b. Bronzes:

The bronze is an alloy of copper and tin and minor percentages of other elements, except zinc, may be added.

Following are the common varieties of bronze:

(i) Bell Metal:

It contains 82% copper and 18% tin. It is hard and brittle. It possesses resonance. It is used for making bells.

(ii) Gun Metal:

It contains 88% copper, 10% of tin and 2% of zinc. It thus contains zinc and forms an exception to the general rule of bronze. It is tough, strong and hard. It resists the corrosion by sea water. It is suitable for sound castings. It is used for bearings, bolts, nuts, bushings and for many items in naval construction and it is so called because this alloy was used for casting into cannons in the middle ages.

(iii) Manganese Bronze:

It contains 56 to 60 per cent copper and remaining is zinc.

Following other elements are also added:

Manganese – 1% maximum

Aluminium – 0.05% to 1%

Lead – 0.40% maximum

Iron – 0.40% to 1%

This alloy resists corrosion by sea water and it is also not attacked by dilute acids. It is used for various ship fittings, shafts, axles, etc.

(iv) Phosphor Bronze:

It contains 89% copper, 10% tin and 1% phosphorus. This alloy is hard and strong. It resists the corrosion by sea water. It is used for subaqueous construction and because of high endurance limit, it can also be used for springs, gears, bearings, etc.

(v) Speculum Metal:

It contains 67% copper and 33% tin. It is silvery in colour. It has a high reflective surface, when polished. This alloy is used in making telescopes.

(3) Magnesium Alloys:

These alloys are light and they can be easily worked. They are used to construct aeroplanes, chair frames, engine parts, etc.

Following are important magnesium alloys:

(i) Dow metal

(ii) Electron metal

(i) Dow Metal:

It contains 4 to 12% aluminium, 0.1 to 0.4% manganese and the rest is magnesium.

(ii) Electron Metal:

It contains 4% zinc, small percentages of copper, iron and silicon and rest is magnesium.

(4) Nickel Alloys:

Following are two important nickel alloys:

(i) Monel metal

(ii) Nickel silver.

(i) Monel Metal:

This nickel alloy contains about 65% nickel, 30% copper and 5% other metals like iron and manganese. It possesses great resistance to corrosive liquids, acids, etc. It retains its physical properties at considerable high temperatures. This alloy is available in different grades and each grade has specific uses. It is mainly used for making tanks in food, textile and chemical industries, valves, tubes, propeller shafts of ships, etc.

(ii) Nickel Silver:

This is also known as the German silver. It is a brass to which the nickel is added.

Its usual composition is as follows:

Copper – 50 to 80%

Zinc – 10 to 30%

Nickel – 20 to 30%

This alloy is of silvery white colour and it offers great resistance to the atmospheric corrosion and organic acids. It is used for making scientific instruments, utensils, typewriter parts, musical instruments, automobile fittings, marine fittings, food-handling equipment, etc.

(5) Steel Alloys:

The properties of steel can be altered by adding small percentages of other elements such as manganese, nickel, copper, etc. Such steel is accordingly designated.

Following are the common varieties of steel alloys:

(i) Chrome-Molybdenum Steel:

In this steel alloy, chromium and molybdenum are added to steel, having carbon content of 0.20 to 0.50 per cent. The percentage of chromium is about 0.40 to 1.10 and that of molybdenum is about 0.20 to 0.40. This alloy is very hard, strong and tough. This alloy is used in aircraft industry, oil industry, etc.

(ii) Chrome-Nickel Stainless Steel:

This alloy of steel contains about 18 to 20 per cent of chromium and 8 to 12 per cent of nickel. It is highly resistant to corrosion. It can be cast, pressed and machined. It is not affected by acids. It is widely used for household utensils, vessels to store acids, dairy plant equipment, etc.

(iii) Chrome-Nickel Steel:

This alloy of steel contains about 0.55 to 1.75 per cent of chromium and 1.10 to 3.75 per cent of nickel. The carbon content of steel varies from 0.17 to 0.43 per cent. This alloy is tough and ductile. It possesses high elastic limit and tensile strength. It is also highly resistant to dynamic stresses. This alloy is used for aeroplanes, engine parts, bearings, pneumatic tools, gears, etc.

(iv) Chromium Steel:

This alloy is popularly known as the chrome steel. It contains 0.70 to 1.20 per cent of chromium. The carbon content of steel varies from 0.17 to 0.55. It possesses extremely high elastic limit. It therefore can withstand abrasion, impact or shock. This alloy is used for cutting tools, files, coil springs for automobiles, ball bearings, etc.

(v) Chromium-Vanadium Steel:

This alloy of steel contains chromium and vanadium. The percentage of chromium is 0.70 to 0.90 per cent and that of vanadium is 0.10 to 0.15 per cent. The carbon content of steel varies from 0.17 to 0.55 per cent. It is highly ductile and can be easily worked. It also possesses high strength. It can be easily welded. It is finely grained. This alloy is used for locomotive springs, bolts, pistons, marine engine construction, etc.

(vi) Cobalt Steel:

This alloy of steel is formed by adding cobalt to high carbon steel. It possesses magnetic properties and addition of about 35 per cent of cobalt to high carbon steel makes a permanent magnet with strong magnetic field.

(vii) Copper Steel:

This alloy of steel contains copper to the extent of about 0.15 to 0.25 per cent. It can offer atmospheric resistance in a better way than ordinary carbon steel and except this, there are no remarkable changes in the properties of steel.

(viii) Manganese Steel:

This alloy of steel contains manganese to the extent of about 1.60 to 1.90 per cent. The carbon content of steel varies from 0.30 to 0.50 per cent. It is hard and strong. It possesses fair ductility and excellent resistance to abrasion. It has a low coefficient of expansion. This alloy is used for points and switches in railway crossings, springs, gears, burglar-proof construction, etc.

(ix) Molybdenum Steel:

This alloy of steel contains molybdenum and manganese. The percentage of molybdenum varies from 0.20 to 0.30 per cent and that of manganese varies from 0.70 to 1.00 per cent. It is hard and less brittle. It offers better resistance to impact and shock. It maintains its properties at high temperatures. It can be easily welded. This alloy is used for axles, springs, bolts, scraper blades, etc.

(x) Nickel-Chromium-Molybdenum Steel:

This alloy of steel contains nickel, chromium and molybdenum. It also contains small percentages of manganese, phosphorus, silicon and sulphur. The percentage of nickel varies from 0.40 to 2.00, that of chromium varies from 0.40 to 0.90 and that of molybdenum varies from 0.15 to 0.30.

The carbon content of steel varies from 0.28 to 0.40. It cannot be easily welded. It does not soften at high temperatures. It can withstand dynamic stresses. This alloy is used for die-casting dies, bucket teeth of dredgers, etc.

(xi) Nickel-Molybdenum Steel:

This alloy of steel contains nickel and molybdenum. It also contains small percentages of manganese, phosphorus, silicon and sulphur. The percentage of nickel varies from 1.65 to 3.75 and that of molybdenum varies from 0.20 to 0.30.

The carbon content of steel varies from 0.17 to 0.23. It does not distort during quenching. It can be easily given heat treatment. It possesses good toughness. This alloy is used in petroleum industry, aircraft industry, etc.

(xii) Nickel Steel:

This alloy of steel contains 3 to 3.50 per cent of nickel. The carbon content of steel varies from 0.15 to 0.50 per cent. It is hard, ductile and resistant to corrosion. This alloy is used for boiler plates, propeller shafts, structural steel, etc.

When nickel content is about 18 to 40 per cent, it is known as the high-nickel steel. The invar is a high nickel steel alloy with 36 per cent of nickel. It has very small coefficient of thermal expansion. It is used for pendulums of clocks and other precision instruments.

(xiii) Tungsten Steel:

This alloy of steel contains tungsten to the extent of about 5 to 7 per cent. The carbon content of steel varies from 0.50 to 1.00 per cent. It is also sometimes known as the high speed steel. It is hard and can maintain its cutting power at high temperature. This alloy is used for drills, lathe tools, cutters, etc.

(xiv) Vanadium Steel:

This alloy of steel contains vanadium to the extent of only about 0.20 per cent and thus a very small quantity of vanadium modifies the properties of steel. It is very strong and ductile. It is capable of resisting shocks and its elastic limit is high. This alloy is used for springs, automobile parts, etc.