In this article we will discuss abour the formation of widmanstatten structure of steels. Also learn about the factors controlling its formation.

Formation of Widmanstatten Structure of Steels:

If a coarse-austenite grained steel is cooled fast but less than its critical cooling rate, then a typical micro-structure develop called widmanstatten structure. (See Fig. 2.38, a typical micrograph illustrating this structure, whereas 2.39 illustrates steel casting resulting, on cooling, in widmanstatten structure, and when heated to above AC3 temperature refines the austenite grains with resultant fine ferrite and pearlite structure).

In Widmanstatten structure, the pro-eutectoid phase (ferrite or cementite depending on the carbon content of the steel) separates not only along the grain boundaries of austenite, but also inside the grains along certain crystallographic planes (octahedral planes) and direction in the shape of plates, or needles forming mesh-like arrangement.

The strain energy factor is least, in the plate shape, when a new phase separates. The preference to form along certain crystallographic planes is to have better crystallographic match between the matrix and the new phase, so that there is less distortion at the interface, which results in lower surface energy.

ADVERTISEMENTS:

The orientation relationship is:

Since the orientation of each grain in original austenite is different, the character of Widmanstatten pattern is also different from grain to grain. Widmanstatten structure is commonly found is steel castings, overheated steels, normalised forgings, rolled, or extrusion products, and weldings.

ADVERTISEMENTS:

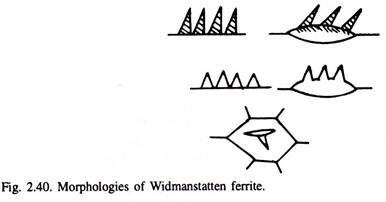

Some common ferrite morphology as widmanstatten is illustrated in Fig. 2.40. Similar morphologies can be obtained for cementite.

Factors Controlling Formation of Widmanstatten Structure:

1. Composition of Steel:

For the formation of widmanstatten structure, reasonably large amount of pro-eutectoid phase should be available to be formed, i.e. steels having carbon less than 0.6% (best in 0.3 to 0.4%C) and more than 0.9% C. Due to the non-equilibrium cooling and non-availability of large grain boundary area, (due to large austenite grains), whole of the proeutectoid phase does not get time to form at the grain boundaries, but precipitates inside the grains too.

ADVERTISEMENTS:

2. Grain Size of Steel:

Larger the austenitic grain size, lesser is the area where proeutectoid phase has to form. So it forms inside the grains, which is further promoted by less time available for diffusion to occur due to faster cooling.

3. Cooling Rate:

Faster cooling of the steel does not allow enough diffusion to be possible, and thus, pro-eutectoid phase precipitates inside the grains too as widmanstatten structure. Due to super-cooling, the plates of non-equilibrium precipitate, requiring less strain energy, form easily, and at interfaces of lower energy.

ADVERTISEMENTS:

Hypoeutectoid steels having widmanstatten structure are characterised by low impact value and low percentage elongation, as the strong peartite is isolated in ineffective patches by weak ferrite along-which crack can readily propagate, and thus, such structures are generally avoided. High silicon, if present in steel castings, modifies the widmanstatten structure to ‘feathery structure’. Hot working and, or normalising help in changing the widmanstatten structure to normal structure.

Fig. 2.39 illustrates how this structure on heating to just above A3 temperature and then slow cooling leads to fine-grained ferrite and peartite. Homogenising time for a widmanstatten structure is less than a slowly cooled structure.

(a) Widmanstatten Side Plates:

These grow from the grain boundary vicinities,

ADVERTISEMENTS:

(b) Widmanstatten Saw Teeth:

These occur as grains that appear to be triangular and develop from grain boundary regions,

(c) Intergranular Widmanstatten Plates:

These occur entirely within the parent grains of austenite.

Widmanstatten structure in hyper-eutectoid steels having large amount of cementite in the matrix of peartite as compared to, when whole of this brittle phase is present at the grain boundaries, results in slightly better properties, i.e., steels are then, less brittle as compared to slowly cooled steels and thus are preferred.

Widmanstatten structure is a very general phenomena, i.e., it is not only common is steels, but also in other alloy systems, when one phase separates from the other by the fall of temperature, such as in α + β brasses, aluminium bronzes, age hardening alloys.