In this article we will discuss about the empirical correlations for free and forced convection.

Bulk Temperature and Mean Film Temperature:

The physical properties (µ, k, ρ, cp) of a fluid are temperature dependent. Undoubtedly the accuracy of the results obtained by using theoretical relations and the dimensionless empirical correlations would depend upon the temperature chosen for the evaluation of these properties. No uniform procedure has been attained in the selection of this reference temperature. However, it is customary to evaluate the fluid properties either on the basis of bulk temperature or the mean film temperature.

The mean bulk temperature th denotes the equilibrium temperature that would result if the fluid at a cross-section was thoroughly mixed in an adiabatic container. For turbulent flow of fluids in ducts, this temperature is very nearly equal to the fluid temperature near the duct axis. In heat exchangers, the fluid flowing through the tubes may be heated or cooled during its flow passage.

The bulk temperature is then taken to be the arithmetic mean of the temperatures at inlet to and at exit from the heat exchanger tube, i.e., tb = (ti + ta)/2. The mean film temperature tf is the arithmetic mean of the surface temperature ts of a solid and the undisturbed temperature t∞of the fluid which flows past it; tf = (ts + t∞)/2.

Local and Average Convective Coefficient:

ADVERTISEMENTS:

Consider the flow condition depicted in Fig. 10.1 where a fluid with velocity U∞ and temperature t∞ flows past a stationary flat plate of length l and width B. If temperature ts at the plate surface is greater than the free stream temperature t∞then convective heat transfer occurs from the plate to the fluid.

The flow conditions vary from point to point on the surface, and as such the convective film coefficient and the heat flux would also vary along the surface. However for an elementary strip of length dx located at a distance x form the leading edge, the convective coefficient can be assumed to be practically constant. The local heat flux is then given by-

Qx = hx dA (ts – t∞) = K (B dx) (ts – t∞) …. (10.1)

Where, hx is the local convection coefficient.

ADVERTISEMENTS:

The total heat transfer rate Q is obtained by integrating the local flux over the entire surface.

Defining an average coefficient for the entire surface, the total heat transfer rate may also be expressed as,

From equations 10.2 and 10.3, the local and average convection coefficients are related by an expression of the form,

The average value of convection coefficient based upon the total surface area is used in the Newton-Rikhman relation to calculate the total amount of heat that is transferred for the given set of conditions. The local convection coefficient becomes the controlling factor when the local temperature in the boundary layer has a certain temperature limit which is not to be exceeded.

Example 1:

Experimental results indicate that the local heat transfer coefficient hx for flow over a flat plate with an extremely rough surface is approximated by the relation-

ADVERTISEMENTS:

hx = a x-0.12

where, a is a constant coefficient and x is distance from the leading edge of the plate. Set up a relation between this local heat transfer coefficient and the average heat transfer coefficient h for a plate of length x.

Solution:

The local and average convection coefficients are related by an expression of the form,

Correlations for Free Convection:

For the usual free convection circumstances, the following dimensionless numbers apply:

The basic equation developed from dimensional analysis for use in determining the value of convection coefficient h is-

Through rigorous experimental tests of free convection with various fluids (both liquids and gases) flowing past horizontal cylinders and vertical plates, the exponents a and b have been found to be numerically same. This permits the correlation 10.5 to be rewritten in the form,

The constant C and exponent m depend upon the nature of flow (laminar or turbulent), geometrical configuration (plate or cylinder) and its orientation (vertical or horizontal). For free convection, the fluid properties needed for the determination of Gr and Pr are generally evaluated at the mean film temperature. The product (Gr × Pr) is often referred to a Rayleigh number, and its value sets the criterion of laminar or turbulent character of flow. Thus,

1. Horizontal Plates, Cylinders and Wires:

(i) Plates- heated surface up or cooled surface down-

a. laminar flow 2 × 105 < Gr Pr < 2 × 107

Nu = 0.54 (Gr Pr) 0.25 … (10.8)

b. turbulent flow 2 × 107 < Gr Pr < 3 × 1010

Nu = 0.14 (Gr Pr) 0.33 … (10.8)

(ii) Plates- heated surface down or cooled surface up –

a. laminar flow 3 × 105 < Gr Pr < 7 × 108

Nu = 0.27 (Gr Pr) 0.25 … (10.9)

b. turbulent flow 7 × 108 < Gr Pr < 11 × 1010

Nu = 0.107 (Gr Pr)0.33 …(10.10)

In these correlations, the characteristic length used in computing the Nusselt and Grashof numbers is the length of the side of a square, mean of the two dimensions of a rectangular surface or 0.9 times the diameter of a circular disk.

(iii) Long cylinder L/D > 60 –

a. laminar flow 104 < Gr Pr < 109

Nu = 0.53 (Gr Pr)0.25 …(10.11)

b. turbulent flow 109 < Gr Pr < 1012

Nu = 0.13 (Gr Pr)0.33 …(10.12)

For cross flow over horizontal pipes,

Nu = 0.37 (Gr Pr)0.25 …(10.13)

The characteristic length is the cylinder diameter.

(iv) Fine horizontal wires D < 0.005 cm

Nu = 0.4 (Gr Pr) 0.0 = 0.4 … (10.14)

The characteristic length is the wire diameter.

2. Vertical Plates and Large Cylinders:

a. laminar flow 104 < Gr Pr < 109

Nu = 0.59 (Gr Pr)0.25 …(10.15)

b. turbulent flow 109, Gr Pr < 1012

Nu = 0.13 (Gr Pr) … (10.16)

The characteristic length is the vertical dimension of the plate or cylinder.

3. Inclined Plates:

Multiply Grash of number by cos ϴ, where ϴ is the angle of inclination from the vertical and use vertical plate constants.

4. Miscellaneous Solids (Spheres, Short Cylinders and Blocks):

The following correlation has been suggested for free convection for a sphere

Nu = 2 + 0.43 (Gr Pr) 0.25 … (10.17)

For higher values (3 × 105 < Gr Pr < 8 × 1010) 0.43 is replaced by 0.50.

For short cylinders (D = H)

Nu = 0.775 (Gr Pr) 0.208 … (10.18)

For other solids

Nu = 0.52 (Gr Pr) 0.25 …. (10.19)

Where, the characteristic length is the distance travelled by a particle in the boundary layer. For rectangular solids, the characteristic length is worked out from the relation

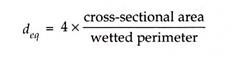

Where, lv and lh refer to the significant vertical and horizontal dimensions. Further when flow is considered through a non-circular conduit such as square, rectangular duct, annular space between concentric pipes and tubes, the significant length is the equivalent diameter defined as,

Example 2:

Two horizontal steam mains with diameters 5 cm and 15 cm are so laid in a boiler house that any mutual heat effect is precluded. The mains are at the same surface temperature of 500°C whilst the ambient air is at 50°C. Work out the ratios of the heat transfer coefficients, and of the heat losses from one metre length of the mains.

Solution:

The steam mains are located in the boiler house where the ambient air is stationary.

The situation then corresponds to that of free convection for which the following correlation applies:

Since both the mains are at the same temperature and are exposed to the same ambient conditions, the relevant fluid properties are same for both.

Example 3:

A spherical heater of 20 cm diameter and at 60°C is immersed in a tank of water at 20°C. Determine the value of convective heat transfer coefficient.

Solution:

At the mean film temperature tf = (60 + 20)/2 = 40°C, the thermo-physical properties of water are:

Correlations for Forced Convection:

For the usual forced circumstances, the following dimensionless numbers apply:

The conventional generalised basic equations for use in determining the value of convection coefficient h are,

The numerical values of the constants and the exponents are determined by obtaining the best fit to the experimental data. The fluid properties needed for calculating the values of dimensionless groups pertaining to forced convection are generally evaluated at the bulk temperature, unless stated otherwise.

Flow passages for fluids in forced convection take many forms. For example the fluid may flow along a flat plate, inside a pipe, across the outside of pipe or wire, or across the outside of tubes in a tube bank array. Each of these geometries will have a different heat transfer characteristic.

A. Laminar Flow:

Plane Surfaces: Flow Past Flat Plates and Walls:

(a) The local film coefficient for laminar flow past a flat plate may be obtained from the correlation-

Nux = 0.332(Rex)0.5 (Pr)0.33 …(10.19)

Where,

(i) Fluid properties are evaluated at the mean film temperature, i.e., arithmetic average of the temperature of the fluid and the temperature of the surface of the plate

(ii) Reynolds number must not be less than 40 000

(iii) Pr must be more than 0.6

For a plate of length l, an average value of Nusselt number or convection coefficient may be obtained by integration.

(b) The following correlation has been proposed for liquid metals –

Nux = 0.565 (Rex × Pr) … (10.23)

For the validity of the above relation, the fluid properties are evaluated at the film temperature and Pr < 0.05

Cylindrical Surfaces: Flow inside Pipes and Tubes:

(a) For uniform heat flux: Nu = 4.36

(b) For constant wall temperature

(i) Slug flow- Nu = 5.78

(ii) Fully- developed flow- Nu = 3.66

(c) The following correlations have been suggested for flow inside tubes

The above identity is valid when –

(i) Pipe length is much greater than diameter,

(ii) Fluid properties are evaluated at the bulk temperature

(iii) Re and Nu are calculated on the basis of pipe diameter as length parameter

(iv) Prandtl number lies in the range 0.5-100

(v) Constant wall temperature and fully turbulent flow.

which is essentially valid for short tubes. The fluid properties are evaluated at the bulk temperature except µs which is calculated at the mean surface temperature. The pipe diameter is the significant length parameter.

Further Re, l/d and µ should have values within the limits:

B. Turbulent Flow:

Turbulent Flow over Flat Plate:

The general equations giving the local heat transfer coefficient for turbulent flow (Rex > 5 × 105) past flat plate are,

Where, the properties are evaluated at the mean film temperature

For a plate of length I, average Nusselt number would be given by-

͞Nu = 0.036 (Rel)0.8 (Pr)0.33 …(10.27)

When the flow lies in the transition range,

͞Nu = 0.036 (Pr)0.33 [(Rel)0.8 – A] …(10.28)

The constant A takes the value 18700 at transitional Reynolds number 4 × 105; and 23100 at transitional Reynolds number 5 × 105.

Turbulent Flow in Tubes:

1. Mc Adam has suggested the following general correlation for heating and cooling of fluids in turbulent flow through long pipes.

Nu = 0.023 (Re)0.8 (Pr)n …(10.29)

Where,

(i) n = 0.4 if the fluid is being heated

= 0.3 if the fluid is being cooled

(ii) Fluid properties are evaluated at the mean bulk temperature

(iii) 1 × 104 < Re < 12 × 104

(iv) 0.7 < Pr < 120 and

(v) l/d > 60

For gases such as air, Pr is essentially constant and can be dropped by changing the constant to 0.02.

2. Colburn proposed a correlation in terms of Stanton number.

St = 0.023 (Re)-0.2 (Pr)-0.667 … (10.30)

Where,

(i) St is evaluated at the mean bulk temperature

(ii) Re and Pr are calculated at the average film temperature

(iii) Re, Pr and l/d should have the values within the limits

Re > 104 ; 0.7 < Pr < 160 ; l/d > 60

3. The Mc Adam’s and Colburn correlations are fairly accurate for temperature difference of 5°C in case of liquids and 50°C for gases.

For greater temperature differences, Sieder and Tate proposed the following correlations,

Where,

(i) All fluid properties except are calculated at the bulk temperature; (i is evaluated at the wall temperature

(ii) Re > 104; 0.7 < Pr < 17000; l/d < 60.

For flow in short passages, these correlations need to be modified to account for the variable velocity and temperature profile along the axis of flow.

The following equations have been suggested:

4. For very large temperature difference (ts – tb) with air, Desman and Sams have suggested the following correlation

Nu = 0.026 (Re)0.8 (Pr)0.4 …(10.33)

Where,

(i) ta/tb upto 3.55

(ii) Re > 104

(iii) Nu and Pr are evaluated at mean bulk temperature

(iv) Re is evaluated at mean film temperature

Turbulent Flow over Cylinders:

The values of constants C and n depend on the flow Reynolds number. Further, all thermo- physical properties of fluids are evaluated at the film temperature.

Turbulent Flow over Spheres:

1. For flow of gases over spheres –

Nu = 0.37 (Re)0.6 … (10.35)

for 25 < Re < 105

Fluid properties are to be evaluated at the film temperature.

2. For flow of liquids past spheres –

Nu = [0.97 + 0.68 (Re)0.5] Pr 0.3

for 1 < Re < 2000

Fluid properties are to be evaluated at the film temperature.