The various considerations involved in the design of screens and screen channels are as follows:

1. Velocity of Flow:

The velocity of flow ahead of and through a screen varies materially and affects its operation. The lower the velocity of flow through the screen, the greater is the amount of screenings that would be removed from sewage. However, the lower the velocity of flow, the greater would be the amount of solids deposited in the channel in which screen is installed.

Hence, the design velocity of flow should be such as to permit 100% removal of material of certain size without undue depositions. As per the Indian Standard IS: 6280-1971 which provides specifications for sewage screens the effective area of opening of the screen (which is the vertical projected area of the screen openings from the invert of the channel to the flow line) should be such that the velocity of flow produced through the screen opening does not exceed 0.9 m/s at maximum or peak flow.

However, velocities of 0.6 to 1.2 m/s through the screen openings for the maximum or peak flows have been found satisfactory. When considerable amounts of storm water (or rain water) are to be handled, approach velocity of about 0.8 m/s is desirable to avoid grit deposition at the bottom of the screen, though lower value of 0.6 m/s is used in current practice.

ADVERTISEMENTS:

Further at low flows the velocity of flow in the approach channel should not be less than 0.3 m/s to avoid deposition of solids. A straight channel ahead of the screen ensures good velocity distribution across the screen and maximum effectiveness of the screen.

2. Loss of Head:

As sewage flows through a screen certain amount of loss of head takes place.

The loss of head through bar screens is a function of-

(i) Bar shape, and

ADVERTISEMENTS:

(ii) Velocity head of the flow between the bars.

Kirschmer has proposed the following equation for head loss:

Kirschmer’s values of (3 for several shapes of bars are given in Table 11.1. The head loss calculated from equation 11.1 applies only when the bars are clean. Head loss increases with the degree of clogging.

Values of C and A depend on screen design factors such as the size and milling of slots, the wire diameter and weave, and particularly the percent of open area, and must be determined experimentally. A typical value of C for a clean screen is 0.60.

The head loss through a clean screen is relatively insignificant. The important determination is the head loss during operation, and this depends on the size and amount of solids present in sewage, the size of apertures, and the method and frequency of cleaning.

3. Materials:

Bar screens are made of steel bars or flats or rods fixed to a suitable steel frame. The minimum cross-section of bars or flats or rods used for bar screens is 10 mm x 50 mm, and are placed with large dimension parallel to the direction of flow. The spacing between the bars or flats or rods should be uniform and preferably so maintained by adequate number of spacers, which should be so located as not to interfere with the raking operation.

ADVERTISEMENTS:

Fine screens are made of brass or bronze plates or wire mesh so as to provide resistance to rust and corrosion. They have perforations or openings of size 1.5 to 3 mm. Fine screens have generally a net submerged open area of not less than 0.05 m2 for every 1000 m3 of average daily flow of sewage from a separate system, the corresponding figure being 0.075 m2 for combined systems.

4. Other Considerations:

(i) The top of screen is provided at least 300 mm above the highest flow level of sewage.

(ii) In case of large sewage treatment plants the screen channel may be suitably divided to have a maximum screen width of 1.5 m.

(iii) The submerged area of the screens including bars and openings should be about 25 to 35 per cent in excess of the cross-sectional area of the approach channel. The area should be considered as the projected area normal to the direction of flow in case of inclined screen. The angle of inclination of manually cleaned screens is between 45° and 60° with the horizontal and that of mechanically cleaned screens is between 60° and 90° with the horizontal.

ADVERTISEMENTS:

(iv) The screen should be embedded in such a manner that the frame, if any, does not offer obstruction to the flow of sewage.

(v) The screen channel invert downstream of the screen is provided with a drop below the invert level of screen channel on the upstream of the screen. In the case of hand operated screens a minimum drop of 150 mm should be provided and in the case of mechanically operated screens a minimum drop of 75 mm should be provided.

(vi) The length of the screen channel should be sufficient so that the screen can be properly housed, enough working space is available, flow gets stabilized and eddies are avoided.

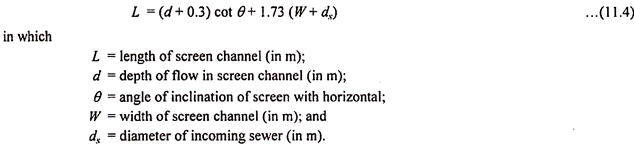

The length of the screen channel is given by the formula:

(vii) The screen channel should be provided with smooth entry and exit arrangements. All the corners should be rounded and the edges should be chamfered near the screen to facilitate the cleaning of the channel near the screen.

(viii) A minimum free-board of 300 mm should be provided, which may be suitably raised where required by turbulent conditions in the channel.

(ix) A bypass arrangement should be provided to take care of abnormally high flow of sewage.

A summary of the design information for bar screens or bar racks is given below:

(i) Minimum bar size = 10 mm x 50 mm

(ii) Clear spacing between bars = 15 mm to 75 mm

(iii) Slope with horizontal-

(a) Manually cleaned = 45° to 60°

(b) Mechanically cleaned = 60° to 90°

(iv) Minimum approach velocity = 0.3 m/s

(v) Velocity of flow through screen openings

= 0.6 m/s to 1.2 m/s

(vi) Allowable head loss = 0.15 m

The Indian Standard IS: 6280-1971 gives detailed specifications for sewage screens.