The following points highlight the nine main properties of moulding sand. The properties are: 1. Permeability 2. Cohesiveness 3. Adhesiveness 4. Plasticity 5. Refractoriness 6. Chemical Resistivity 7. Binding Property 8. Flowability 9. Green Strength.

Property # 1. Permeability:

The passage of gaseous materials, water and steam vapour through the moulding sand is related to porosity or in other words permeability.

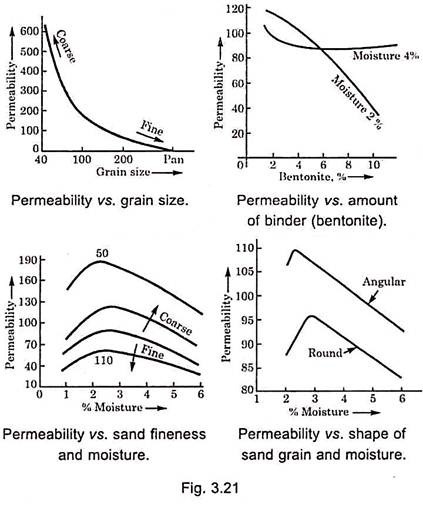

The permeability of sand depends upon the following factors:

(i) Size of the grain (varying over the wide range of 50 microns to 3360 microns).

ADVERTISEMENTS:

(ii) Shape of the grain (round, angular, sub-angular or compound), the round shape being more favourable for porosity.

(iii) Compactness density has also a bearing on the permeability.

(iv) Moisture content in the moulding sand affects permeability since the excess moisture tends to collect in the interstices.

(v) Bonding content also affects the porosity of the moulding sand through the interstitial structure.

The sand used for casting must be porous enough, so as to allow the gaseous material, water and steam vapours to escape freely when the molten metal is poured into the mould. Molten metal contains some dissolved gases, which are evolved on solidification.

Further, molten metal in contact with moist sand forms steam and vapour which must find passage to escape completely. Insufficient porosity of moulding sand leads to casting defects such as gas holes and pores. The moulder has some control over permeability; hard ramming lowers the permeability, but this is relieved by liberal venting.

Fig. 3.21 shows how permeability is affected by various factors.

Property # 2. Cohesiveness:

ADVERTISEMENTS:

The ability of sand particles to stick together is termed as cohesiveness or the strength of the moulding sand.

Strength or cohesiveness of sand depends upon the following factors:

(i) Grain size and shape, which affect the strength characteristics to a considerable extent.

(ii) Mixture of various-size grains.

ADVERTISEMENTS:

(iii) Bonding material or bond content and its distribution.

Bond strength is determined by the alumina (clay) content. Clay should be present as a thin, tenacious film on each grain of sand. Sharp sands having smooth oval grains are not easily bonded and clay helps in bonding.

(iv) Moisture content—a major factor that affects strength of sand.

Moulding sand must have a good strength, otherwise it may lead to collapse of the mould or its partial destruction during conveying, turning over or closing. Cohesion must be retained, when the molten metal enters the mould (bond strength) and sand should not be washed away during pouring.

Property # 3. Adhesiveness:

ADVERTISEMENTS:

The sand particles must be capable of sticking to the other bodies, particularly to the moulding box and it is only due to this property that sand mass is held in the moulding box properly and does not fall when the mould is moved. At the same time, the sand must not stick to the casting and strip off easily, leaving a clean surface.

Property # 4. Plasticity:

It refers to the condition of acquiring predetermined shape under pressure and to retain it, when the pressure is removed. In order to have a good impression of the pattern in the mould, moulding sand must have good plasticity. Generally, fine grained sand has better plasticity. It depends on the content of clay, which absorbs moisture, when sand is dampened.

Property # 5. Refractoriness:

It is the ability of the silica sand to withstand high heat without breaking down or fusing. Sand with poor refractoriness may burn at high temperature. The fusion point of moulding sand can be increased by removing the impurities, particularly metallic-oxides. Sand also should not form glassy mass which hampers stripping.

Property # 6. Chemical Resistivity:

Moulding sand should not chemically react or combine with molten metal so that it can be used again and again.

Property # 7. Binding Property:

Binder allows sand to flow to take up pattern shape. It must not be so strong that break out becomes difficult, nor should it be so weak that it allows surface skin of casting to break.

Property # 8. Flowability:

This is similar to plasticity. It is the ability of sand to take up the desired shape. Sand must be able to transmit the blows throughout during ramming.

Property # 9. Green Strength:

It depends on:

(a) Grain size,

(b) Shape and distribution of sand grains,

(c) Type and amount of clay or other binder, and

(d) Moisture content.

Dry compressive strength of a moulding-sand mixture increases as moisture is added, until the sand is too wet to be workable (Fig. 3.23).

Fig. 3.24, shows how the green strength of moulding sand varies with other characteristics.