In this article we will discuss about:- 1. Size of the Fluorescent Lamp 2. Construction, Functioning & Accessories of a Fluorescent Lamp 3. Mode of Functioning of a Starter of Fluorescent Lamp 4. Power Factor of the Fluorescent Lamp 5. Power Factor of the Fluorescent Lamp 6. Suppression of Radio Interference in the Fluorescent Lamp 7. Use of Two or More Fluorescent Lamps Together and Other Details.

Contents:

- Size of the Fluorescent Lamp

- Construction, Functioning & Accessories of a Fluorescent Lamp

- Mode of Functioning of a Starter of Fluorescent Lamp

- Power Factor of the Fluorescent Lamp

- Power Factor of the Fluorescent Lamp

- Suppression of Radio Interference in the Fluorescent Lamp

- Use of Two or More Fluorescent Lamps Together

- Stroboscopic Effect of the Fluorescent Lamp

- Fluorescent Lamps in D.C. Circuits

- Span of Life of a Fluorescent Lamp

- Use of Fluorescent Lamps in Workshops etc.

1. Size of the Fluorescent Lamp:

This lamp belongs to gas-discharge group of lamps and is hot cathode type. That is why the usual supply voltage for such a lamp is from 110 to 250 volts. The word ‘fluorescent’ indicates what is brightened by itself. The inner surface of the tube of this lamp is coated with something which becomes self-brightened when electric current flows through it. Usually the powder of zinc silicate, cadmium silicate, calcium tungstate etc. is applied on the inner surface for coating.

ADVERTISEMENTS:

Usually 20-watt and 40-watt fluorescent lamps are available in the market, but 15-, 30- and 80-watt tubes are also manufactured. All these lamps are generally used in a.c. circuits, although in d.c. circuits also tube lights are widely used. Lamps for a.c. circuits are suitable for supply pressures ranging from 110 up to 250 volts where frequency varies between 50 to 60 hertz.

An 80- watt lamp is 152 cm long, a 40-watt lamp is 122 cm long, and the lengths of less wattages are still less. Greater the wattage of the lamp, more is its working efficiency. The lamps may be installed in vertical or horizontal position, but it is better to fix them horizontally. A room is less heated with a fluorescent lamp than with an ordinary filament lamp of the same wattage.

The reason behind it is that, the efficiency of illumination of a fluorescent lamp is about three times that of filament lamp. Whenever current flows through a lamp, electrical energy is converted into heat and light. For consumption of every watt of electricity, the illumination obtained from a fluorescent lamp is much more than that obtained from a filament lamp. Therefore, heat generated by a fluorescent lamp is less.

As a result, for the same illumination, a fluorescent lamp consumes less wattage of power than a filament lamp. But the colour of light emitted by a fluorescent lamp is different from that emitted by a filament lamp. The colour of sunlight is the most comfortable colour for our eyes, and a filament lamp emits yellowish light similar to sunlight.

ADVERTISEMENTS:

Hence, the three colours available from fluorescent lamp— ‘daylight’, ‘warm white’ and ‘natural’—appear to be artificial to us. Besides, in the light of a fluorescent lamp in a.c. circuits the rotating parts of a machine (whenever the machine works) appear’ to be moving intermittently or the machine may seem to rotate with, a speed much lower than its actual speed. This is known as stroboscopic effect. This effect is definitely a disadvantage.

Generally fluorescent lamp is used in shops, factories, cinema halls etc. Many people use it in their residential house also. In the light of many fluorescent lamps, it is difficult to identify colours.

2. Construction, Functioning & Accessories of a Fluorescent Lamp:

From the point of view of construction, a fluorescent lamp is 122 cm or 152 cm long (depending upon wattages of the lamp) glass tube the inner surface of which is coated with fluorescent powder and the two ends are sealed with brass or aluminium caps (Fig. 212). On the outer surface of each cap two small brass or aluminium pins project out. These two pins are connected with a coiled filament inside the tube.

ADVERTISEMENTS:

The filament wire is coated with such a chemical that as soon as current flows through it, the filament emits electrons. These electrons strike against the fluorescent powder on the inner surface of the tube and brightens it up. As a result the entire length of tube becomes luminous.

Fig. 214 shows a two-pin lamp-holder. Inside the holder there are two contacts shaped <>. The two pins of a cap touch these contacts and the electrical connection is complete through these. Two ends of a filament are connected to two contacts. Connections inside a holder are shown in Fig. 213.

Unlike filament lamp a single switch is not sufficient for the operation and control of the circuit of a fluorescent lamp. The accessories used for this lamp are of two kinds. One of these is a coil wound on a laminated iron core. This coil is known as choking Coil or commonly called a ballast. It is connected in the circuit to check the continuous growth of current after the tube becomes luminous. Choking coil is placed on the side of the supply point in series with the tube.

To explain its function it may be said that as the gas (ionised) becomes warmer, more current can easily flow through it, i.e. the resistance of a gas decreases with the rise of temperature. Hence, longer the lamp works, current flowing through it gradually becomes more and more. Temperature goes on rising so much so that at a certain stage the electrode may be melted. The ballast prevents this eventuality.

Since electric current never flows through cold electrodes and cold gas, second accessory is needed to send that amount of current through the two electrodes for a while so that within a moment the electrodes become heated and start emitting electrons. For this purpose electrodes must be short-circuited. But the moment the electrodes warm up and start emitting electrons, the short-circuit must be broken.

All these functions are performed by a starter which works automatically. This second accessory is known as starting device or starter. A starter is usually provided with a separate holder. Fig. 215 shows an automatic starter and its holder is shown in Fig. 216. The arrangement provided in such a starter renders wrong connection impossible.

ADVERTISEMENTS:

It will be seen in Fig. 215 that only two of the four contacts of a starter in the form of pins have, heads, the other two have no head. In Fig. 216 it will be seen that only two of the four sockets which are rather long can easily house the contacts with heads and not the other two contacts. So there is no probability of wrong connection or reverse connection.

Momentarily it short-circuits the two electrodes, and after the gas becomes ionised, it opens up this short-circuit. For this function one terminal of an electrode coil at one side is connected to a supply line, while its other terminal is connected to the starter.

The other side of the starter is connected to one terminal of the other electrode coil. Current from the line at first enters into one electrode. From there it goes to the other electrode through the starter, and finally flows back to the supply line through the choking coil.

These connections of a lamp are shown in Fig. 217.

3. Mode of Functioning of a Starter of Fluorescent Lamp:

The construction of a starter as mentioned above will be discussed now. From this discussion it will be clear how a starter functions automatically.

The starter described below is like a glass bulb of a filament lamp. In place of filament there is mechanism of starting. The essential part of this mechanism is a bi-metal strip shaped like a horse-shoe and made of two different metals such as iron and brass. Its two ends are connected in series with two electrodes of the tube.

The glass bulb of the starter is filled with such a gas as would be easily ionised. The bi-metal strip becomes heated when current flows through it. Anything made of metal expands in size when heated, but all the metals do not expand equally for the same temperature rise. If this bi-metal strip is considered to be made of an iron strip and a brass strip joined together, brass strip will expand more than the iron strip when heated together.

If the iron strip is placed at the inner side of the brass strip, then owing to brass expanding more than iron, the open mouth of the horse-shoe strip will close up. On the other hand, if the brass strip is placed at the inner side of the iron strip, closed mouth of the horse-shoe strip will open up.

Now, let the single-pole switch of the fluorescent lamp is switched on. Instantly current flows through one electrode of the lamp, then through bi-metal strip of the starter and finally it flows back to the supply line through the other electrode of the lamp. As a result two electrodes become heated. Simultaneously, the bi-metal strip of the lamp will also be heated.

By the time the electrodes become red hot and emit electrons, the bi-metal strip closes up its mouth, i.e. short-circuits itself. So the strip no longer carries current. Hence gradually it cools down and the mouth of the strip opens up again. But in the mean time the gas becomes ionised and, therefore, luminous. Hence, the function of the starter ceases. The time required for all these operations is not more than two seconds.

4. Power Factor of the Fluorescent Lamp:

The continuous growth of discharge current in the lamp is checked by means of resistance coil in d.c. circuits and choking coil in a.c. circuits. D.C. circuits suffer no inconvenience from this ballast, but a kind of trouble arises from it in a.c. circuits.

The frequent reversal of current in a.c. circuits results in the corresponding reversal of magnetism due to this current. The frequent reversal in the direction of magnetic lines of force induces an e.m.f. in the choking coil. This induced voltage not only opposes the supply pressure, but it also prevents the current wave to oscillate together with the wave of supply voltage, i.e. it makes the current lagging behind the supply voltage and thereby causes a loss of power.

In practice, it is always found that the power factor of a circuit goes down when choking coil is used in the circuit. As the power factor decreases, current flowing through the circuit increases in the same proportion.

This increased current:

(i) Increases the IR-drop and reduces the working voltage of the circuit,

(ii) Produces excessive heat in the circuit (the circuit conductors may be excessively heated and even melt down; to prevent this, bigger size of conductors are to be used),

(iii) Makes the electrodes of the fluorescent lamp unserviceable quickly.

On the other hand, the use of choking coil is indispensable as explained earlier. Hence, a remedy against the above disadvantages is to be sought for. The remedial measure is to connect a capacitor or condenser in parallel with each lamp circuit. Usually a capacitor of capacitance about 7.5 to 8.0 microfarad is connected in the circuit for each lamp. According to wattages of the lamp a capacitor of suitable size is available in the shop from where the lamp is purchased.

If the power factor of the circuit is to be improved, a fluorescent lamp should be connected as showing in Fig. 219.

5. Suppression of Radio Interference in the Fluorescent Lamp:

In the vicinity of a fluorescent lamp if there be a radio set, disturbance is created in its sound. This is known as ‘Radio Interference’.

Electrons are emitted from the electrodes of a fluorescent lamp. These electrons strike against the aerial of a radio set and the impact of this strike is felt in the set. For the same reason a clicking sound is heard in a set when a fan in the room is switched off. The remedy of this disturbance is to place a radio set at least 3 metres away from a fluorescent lamp. Radio interference also takes place when the wiring of a lamp passes very near the aerial wire of a set.

In order to prevent radio interference a capacitor and a resistance are connected in series, and this series combination is then put in parallel with the fluorescent tube. Such a connection is shown in Fig. 220. The capacitor used for this purpose has a capacitance of about 0.02 micorfarad and the resistance to be used in series with it is more or less 100 ohms.

6. Use of Two or More Fluorescent Lamps Together:

Where a number of fluorescent lamps are to be used, two or more lamps can be connected together in a single circuit. In a.c. circuits different arrangements can be made for this purpose. Generally, equipment for arranging to light a single tube or two tubes together are available in the market.

The advantage of lighting more than one lamp together is that, the quantity of wire required for the wiring is less. For brighter illumination two or even three tubes are included within the same reflector. If two lamps are to be lighted together, connections should be made as shown in Fig. 221. Lamp no. 2 has only a choking coil in series, while lamp no. 1 has a choking coil as well as a capacitor in series.

The size of this capacitor is about 0.25 microfarad. Such arrangement is worthy of keeping in mind. The power factor of the circuit does not go down with this arrangement. In workshops etc. where a large number of fluorescent tubes are used for illumination, a single large capacitor of suitable size is enough for improving the power factor of the group of lamps instead of using a small capacitor with each lamp.

7. Stroboscopic Effect of the Fluorescent Lamp:

An alternating current changes in magnitude as well as in direction at every instant. Whenever the direction of the flow of current changes, momentarily the circuit remains without current. At that instant the lamp is put out, but human eye cannot perceive the same.

Just as the cinema films move very fast before the light and the motion is not perceptible to eye, so also the zero value of instantaneous current. It is true that there is no trouble for ordinary work on this account, but danger may happen in workshops where there are rotating machines. The usual frequency of alternating current in our country is 50 hz. So the fluorescent lamp is off (50 x 2=) 100 times in a second. As a result, a rotating machine may appear to be moving much slower than its actual speed. This is known as ‘Stroboscopic Effect’.

It has been observed on a cinema screen that the wheels of a moving car sometimes appear to be rotating in the opposite direction. This is also due to stroboscopic effect. Such false view of a rotating machine may lead to danger.

Measures adopted to remove this difficulty are stated below:

In single-phase a.c. circuits simultaneous use of two fluorescent tubes as shown in Fig. 221 will improve the power factor as well as eliminate the stroboscopic effect. The current drawn by the lamp having only a choking coil in series will lag behind the applied voltage, while the current drawn by the lamp having both choking coil and capacitor in series will be almost in phase with the applied voltage. As a result, the two lamps can never be off at the same instant. Thus, the fear of stroboscopic effect is removed.

If the circuit is three-phase a.c., three tubes placed under the same reflector are to be energised, each from a separate phase. If, however, the number of lamps is more, they may be divided among the three phases. This arrangement also makes the system free from stroboscopic effect.

8. Fluorescent Lamps in D.C. Circuits:

The advantages and disadvantages of the use of fluorescent lamps in d.c. circuits have already been discussed. Nevertheless, these lamps are used in many d.c. circuits. The advantage of d.c. is that the question of power factor does not arise and, therefore, no capacitor is used. Only one capacitor may be used for suppression of radio interference. Usually a resistance is connected in series with this capacitor.

Another resistance is connected in series with choking coil also. This resistance serves the purpose of choking coil in a.c. circuit under steady condition, i.e. by causing a drop in supply voltage across it, this resistance prevents the current to increase gradually after the tube becomes luminous. Although choking coil does not perform the steady state function, it has to be included in d.c. circuits for its transient function in providing the initial inductive surge for starting the discharge.

A tube used in d.c. circuit is apt to develop a fault. Since direct current flows in one direction only, mercury begins to be deposited at one end of the tube after a few days of use. As a result of mercury coming in contact with fluorescent powder on the inner surface of the tube, the lamp becomes unserviceable in the long run. This does not happen with alternating current. In order to increase the span of life of a lamp in d.c. circuit, a change-over switch is provided in the circuit in place of an ordinary tumbler switch.

Every time the lamp is switched on, changeover in connection of the lamp circuit with the supply line is effected. This ensures a change in the direction of the flow of current every time the lamp is lighted. The flow of current through a lamp in d.c. circuit is controlled by a resistance connected in series with the choking coil. As this resistance causes a power loss, the efficiency of a fluorescent lamp in d.c. circuit is much less than that of a lamp in a.c. circuit.

9. Span of Life of a Fluorescent Lamp:

A fluorescent lamp becomes unserviceable even before the electrodes burn out. There are two reasons behind it. Firstly, the fluorescent powder on the inner surface of the tube includes some mercury which, in course of time, becomes black and darkens the glass tube. As a result, the luminous intensity emitted by the lamp is reduced. Secondly, the metal of the electrodes wears out in the long run.

When it is observed that the two ends of the tube are becoming dark, it is to be concluded that the electrodes Eire nearly worn out. This is the last stage in the life of a lamp. Like all other lamps, a fluorescent lamp also begins to be depreciated from its-very first use. But the extent of darkening developed in the first 100 hours of burning becomes double after the next 1,000 hours.

Hence, the intensity of illumination available from the lamp after first 100 burning hours is to be reckoned. The lamp lasts longer if it is kept burning every time it is switched on. Immediately after switching on, whenever a lamp suddenly lights up only-to-be put out in the next moment, it is to be understood that the life of the lamp has at last come to an end. At this stage often the two ends of the tube become excessively bright. It should then be discarded and replaced by a new tube.

After expiry of the span of life as fixed by the manufacturer in terms of burning hours, a lamp may remain burning and be trouble-free even. Nevertheless, the manufacturers themselves recommend rejection and replacement of tube after the expiry of its normal life period.

They justify their recommendation by stating that, at this stage luminous intensity of the lamp becomes less, while the running expenses go up. For these reasons a proper account of burning hours is to be maintained for each lamp. After expiry of specified burning hours, the lamp should be discarded and replaced in spite of no trouble.

Good result is obtained if the lamp and its all other accessories such as capacitors of suitable sizes, proper size of choking coil etc. are manufactured by the same manufacturers and the connection of the lamp is accomplished according to their direction.

10. Use of Fluorescent Lamps in Workshops etc.:

In places like workshops etc. where a large number of fluorescent tubes are used, different varieties of arrangements of the tubes yield different varieties of utility. It has been observed that by the same kind of installation in the same pattern of arrangement, illumination suffers or there is wastage of light rays. Given below are four kinds of usage and practice any one kind of which may be selected and used as required.

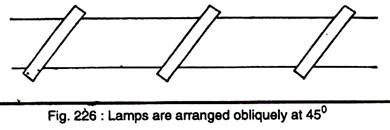

At first it appears in mind to arrange all the tubes either length-wise as shown in Fig. 223 or cross-Wise as shown in Fig. 224. Besides these, two more arrangements can also be adopted for the lamps. These arrangements are shown in Fig. 225 and Fig. 226. Now, the merits and demerits of different arrangements will be discussed.

If the height of the ceiling above the floor is less than 3 metres, arrangement shown in Fig. 223 will result in less wastage of light. If the lamps are hung in a cross-wise manner as shown in Fig. 224 and the lamps are very near (abour 120 cm or more) the job or working table, the illumination available is about the same as that obtained from the arrangement shown in Fig. 223. The additional advantage of this arrangement is that, if the jobs are arranged parallel to the table, less shadow is cast in comparison to first method.

But if the height of the lamps exceeds 3 metres, they may be installed as per arrangements shown in Fig. 225 and Fig. 226. If at any place lamps are arranged as per Fig. 225, light rays from the lamps will illuminate the place uniformly whatever may be the arrangement of the furniture. But if the light rays are to come from the left corner of the front side on a working table or on a job as is often necessary in a drawing office, the lamps should be arranged in parallel but obliquely at 45° as shown in Fig. 226. With this arrangement a person may stand at any side of the table, but the light rays will always come from the front left corner.