The dynamometers that come under this category are: 1. The Prony Brake Dynamometers 2. The Rope-Brake Dynamometer 3. Eddy Current Dynamometer 4. The Electric Dynamometer 5. Swinging Field D.C. Dynamometer 6. Hydraulic Dynamometer.

Type # 1. The Prony Brake Dynamometers:

A simple type, known as the Prony brake is shown in Fig. 25.7. It consists of two blocks of wood, each of which embraces rather less than one half of the pulley rim. The two blocks can be drawn together by means of bolts, cushioned by springs, so as to increase the pressure on the pulley. One block carries an arm to the end of which pull can be applied by means of a dead weight or spring balance. The friction torque on the pulley may be increased until it balances the torque due to the available power.

When the brake is clamped to the fly wheel, the frictional force F = (F/2 + F/2) at the brake shoes tends to turn the brake with the flywheel. However, the knife edge on the beam rests on scales and prevents motion of the brake. The force P, which is weighed by the scales, consists of the reaction produced by friction and a portion of the weight of the brake, called the tare—unless there is a counterweight to balance the brake about the centre line of the flywheel. To find the tare, support the brake on the edge at B and weigh the tare on the scales. Thus the net force on the scales produced by the frictional moment is (P-tare).

Type # 2. The Rope-Brake Dynamometer:

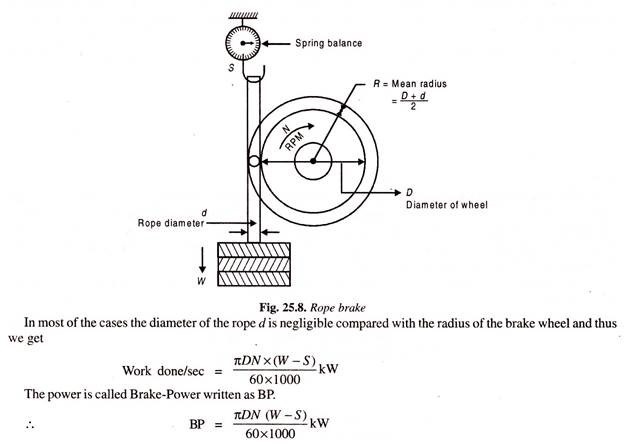

Figure 25.8 shows a rope brake dynamometer. In this brake two or more ropes rest on the rim of a pulley. They are spaced evenly across the width of the rim by means of wooden blocks positioned at different points round the rim. The total pull on the slack ends of the ropes is registered on a spring balance, while the pull on the tight end is provided by dead weights. Friction torque on the pulley may be increased by increasing the dead load by addition of weights.

When the speed of the engine is constant, the friction Torque counterbalances the torque due to available power of the engine.

ADVERTISEMENTS:

We have seen above that the brake power BP is less than the indicated power IP because of the power lost in friction between the various parts of the engine. The power lost in friction is called Friction Power (FP).

The ratio of the power available at the engine crankshaft to the power developed in the cylinder is known as the Mechanical efficiency of the engine.

Thus we see that the aim of the designer is to reduce the friction power of the engine as far as possible.

ADVERTISEMENTS:

Efficiency may well be thought of in its simplest form as output divided by input. The output of a power cycle, which is a thermodynamic cycle for production of power, is the network; the input is the heat added to the working substance from an external source of heat QA. The network of the cycle (Wout – Winput) is taken as the output of the power cycle because of the gross work Wout is used to supply the energy Win to drive the pump.

ADVERTISEMENTS:

Therefore, thermal efficiency can be expressed as the ratio of the network output to the heat energy required to produce that work output.

If the work output in question is the shaft work or shaft power or BP, then the thermal efficiency is called Brake Thermal Efficiency (B. Th. E.) ηthb.

If the work output in question is the developed work called indicated work, the thermal efficiency is called Indicated Thermal Efficiency. (I. Th. E.)ηthi.

Indicated Thermal efficiency is given by-

Mass of fuel used in kg/hour/IP is called Indicated specific fuel consumption (kg/kWH). Similarly, Brake thermal efficiency is given by-

Type # 3. Eddy Current Dynamometer:

One of the oldest forms of dynamometers is the eddy-current dynamometer. The simplest form consists of a disc which, driven by the engine under test, turns in magnetic field. The strength of the field is controlled by varying the current through a series of coils located on both sides of the disc. The revolving disc acts as a conductor cutting the magnetic field. Currents are induced in the disc and, since no external circuit exists, the induced currents heat the disc. For larger power absorptions, the heating of the disc becomes excessive and difficult to control.

In this device the eddy currents are induced in the stator for ease of cooling. A stator or a housing a is supported on trunnion bearings b so that any tendency of the stator to rotate is read on the fixed scale c. Inside the stator is rotor d, keyed to the shaft e and provided with the f not shown passing close to the smooth face of the stator. When the rotor is turned, the flux enters the rotor principally through the ends of the teeth.

As these teeth move, the lines of magnetic flux are caused to sweep through the iron of the stator: the flux induces eddy currents in the stator and tends to rotate the stator in the same direction as the shaft. Coil g when energized with direct current, magnetizes the stator and rotor, with flux lines encircling the coil. The temperature rise of the stator is controlled by the flow of water in channels h. The generator i supplies supplementary excitation for the field coils. If this unit is used, it can cause a steep change in excitation as the engine speed increases, thereby tending to hold the speed constant.

Type # 4. The Electric Dynamometer:

The electric generator can be used for loading the engine, but the output of the generator must be measured by electrical instruments and corrected in magnitude for generator efficiency. The electric load connected to the generated may be Lamp-bank used in laboratory work.

Type # 5. Swinging Field D.C. Dynamometer:

DC shunt motors are used as swinging field dynamometer. DC motor is supported in trunnion bearing to measure the reacting torque that the outer stator and field coil tend to rotate due to magnetic drag. The torque is measured with an arm and swinging equipment and spring scale in the usual manner.

This shunt motor dynamometer can run as a generator and motor also. That is it is reversible and it works as a motoring and power generating unit. When it is used as a generator, the electrical energy produced is dissipated in resistor. When used as motoring device dc energy is supplied from outside and used as starting device for an engine. The load and operation is controlled by varying field current.

Type # 6. Hydraulic Dynamometer:

The hydraulic dynamometer works on the principle of dissipating the power in the fluid friction rather than in dry friction. In principle its construction is similar to that of a fluid flywheel. It consists of an inner rotating member or impeller coupled to the output shaft of the engine. This impeller rotates in a casing filled with some hydraulic fluid. The outer casing, due to the centrifugal force developed, tends to revolve with the impeller, but is resisted by a torque arm supporting the balance weight.

The frictional forces between the impeller and the fluid are measured by the spring balance fitted on the casing. The heat developed due to the dissipation of power is carries away by a continuous supply of the working fluid, usually water. The outer can be controlled by regulating the sluice gates which can be moved in an out to partially or wholly abstract the flow of water between impeller and the casing.